TEL:+86 0536-6162866+86 187-6464-2379

ADD:No.19, Shunde Road, Zhucheng City, Shandong, China

WEB:www.cntianlang.com

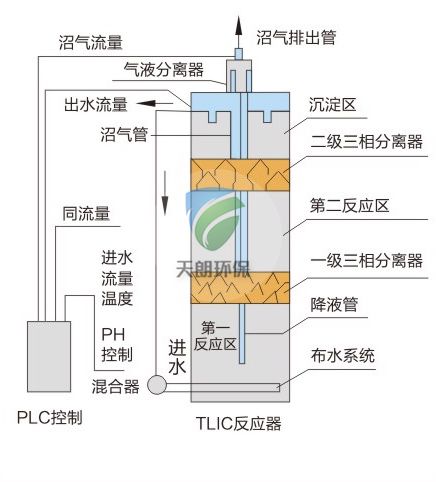

Ic anaerobic reactor

-

MS:Katherine Wong

+86 187-6464-2379

-

TEL:+86 0536 6162866

MAIL:sales@cntianlang.com

-

Product name:Ic anaerobic reactor

Details:

The TLIC (internal circulation) reactor is a new generation of high-efficiency anaerobic reactor. The wastewater is in the reactor from bottom to top, the pollutants are adsorbed and degraded by the bacteria, and the purified water flows out from the upper part of the reactor.

The TLIC is made up of two layers of similar UASB reactors in series. According to the function, the reactor is divided into five zones from bottom to top: mixing zone, first anaerobic zone, second anaerobic zone, sedimentation zone and gas-liquid separation zone.

1. Mixing zone: The water in the bottom of the reactor, the granular sludge and the mud-water mixture refluxed in the gas-liquid separation zone are effectively mixed in this zone.

2. The first anaerobic zone: the muddy water mixture formed in the mixing zone enters the zone, and most of the organic matter is converted into biogas under the action of high concentration sludge. The upward flow of the mixed liquid and the severe disturbance of the biogas cause the sludge in the reaction zone to expand and fluidize, which strengthens the contact of the muddy water surface, and the sludge thus maintains high activity. As the biogas production increases, a portion of the muddy water mixture is lifted by the biogas to the gas-liquid separation zone at the top.

3. Gas-liquid separation zone: The biogas in the ascending mixture is separated from the muddy water and discharged to the treatment system. The mud-water mixture is returned along the return pipe to the lowermost mixing zone, and the sludge and water at the bottom of the reactor are sufficient. Mixing, the internal circulation of the mixture is achieved.

4. The second anaerobic zone: the wastewater treated by the first anaerobic zone, except for a part of being upgraded by the biogas, passes through the three-phase separator to enter the second anaerobic zone. The sludge concentration in this area is low, and most of the organic matter in the wastewater has been degraded in the first anaerobic zone, so the amount of biogas generated is small. The biogas is introduced into the gas-liquid separation zone through the biogas pipe, and the disturbance to the second anaerobic zone is small, which provides favorable conditions for the sludge to stay.

5. Precipitation zone: The muddy water mixture in the second anaerobic zone is subjected to solid-liquid separation in the sedimentation zone, the supernatant liquid is discharged from the outlet pipe, and the precipitated granular sludge is returned to the sludge bed of the second anaerobic zone.

It can be seen from the working principle of the IC anaerobic reactor that the reactor is realized by a two-layer three-phase separator to obtain a high sludge concentration; the muddy water is fully contacted by a large amount of biogas and the internal disturbance of the internal circulation, and a good mass transfer effect is obtained. .

The TLIC anaerobic reactor has the following advantages over the UASB reactor:

1 organic load is high. The internal circulation increases the liquid phase rising flow rate in a reaction zone, and strengthens the mass transfer between the organic matter and the granular sludge in the wastewater, so that the organic load of the IC anaerobic reactor is much higher than that of the conventional UASB reactor.

2 Strong anti-impact load capacity and good running stability. The formation of the inner circulation makes the actual water volume in the reaction zone of the TLIC anaerobic reactor much larger than the influent water volume. For example, when treating wastewater equivalent to the concentration of beer wastewater, the circulating flow rate can reach 2 to 3 times of the influent flow rate; When the wastewater is used, the circulating flow rate can reach 10 to 20 times. The circulating water dilutes the influent water, improves the reactor's anti-shock load capacity and acid-base adjustment ability, and the second reaction zone continues to be processed, and the operation is generally stable.

3 Infrastructure investment province, with a small footprint. When the same wastewater is treated, the volumetric load of the TLIC anaerobic reactor is about 4 times that of the conventional UASB, so the required volume is only 1/4 to 1/3 of the UASB, saving capital investment. In addition, the IC anaerobic reactor adopts a thin and tall tower shape with a height to diameter ratio of 4 to 8, so the floor space is small, and it is especially suitable for enterprises with tight use.

4 energy saving. The internal circulation of the TLIC anaerobic reactor is realized by the lifting of biogas, which does not require external power and saves the energy of recirculation. It has been applied to large starch plants, alcohol wastewater, biopharmaceutical plants, pesticide wastewater treatment systems.

Tel

Tel Home

Home Products

Products